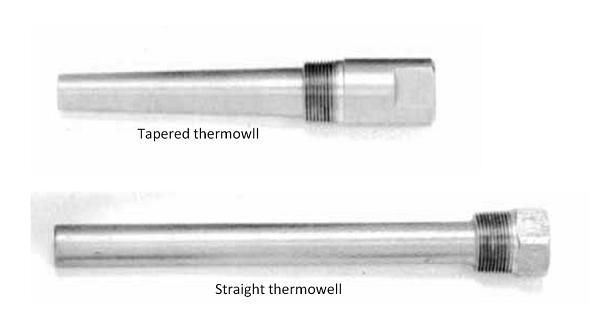

Tapered thermowells are a type of thermowell used in

temperature measurement applications. A thermowell is a

protective sheath or tube inserted into a process or fluid

stream to house a temperature sensor, such as a thermocouple

or RTD. It helps protect the sensor from the surrounding

environment, provides mechanical strength, and allows for easy

removal or replacement of the sensor without interrupting the

process. Tapered thermowells, as the name suggests, have a

tapered shape. The diameter of the thermowell gradually

decreases from the mounting end to the tip. This tapered

design offers several advantages:

Advantages:

Improved Response Time: The tapered shape of the

thermowell reduces the lag time in temperature measurement. By

decreasing the diameter towards the tip, the thermowell allows

for faster heat transfer between the process fluid and the

temperature sensor. This results in a quicker response time

and more accurate temperature measurements.

Reduced Vibration Effects:

Tapered thermowells are less prone to vibration-induced

stresses and resonances compared to straight thermowells. The

tapered design helps dampen vibrations that can affect

temperature readings. This is especially beneficial in

applications with high fluid flow rates or mechanical

vibrations.

Enhanced Self-Cleaning:

The tapering profile of the thermowell promotes self-cleaning.

As the fluid flows past the thermowell, any debris or deposits

are more likely to be swept away due to the changing diameter.

This reduces the accumulation of contaminants on the

thermowell's surface, ensuring more accurate and reliable

temperature measurements.

Lower Pressure Drop:

Tapered thermowells can have a lower pressure drop compared to

straight thermowells. The reduced cross-sectional area along

the length of the thermowell allows for smoother fluid flow,

minimizing the impact on the process and system pressure.

Applications -

Tapered thermowells find application in various industries

and temperature measurement scenarios where fast response

times and accurate temperature measurements are crucial.

Here are a few examples of their applications:

1. Process Industries: Tapered thermowells are commonly used

in process industries such as chemical, petrochemical, and

pharmaceutical plants. In these industries, temperature

measurements are critical for process control, safety, and

monitoring. Tapered thermowells can be utilized in processes

with rapid temperature changes or in applications where

quick response times are required to ensure accurate and

timely temperature measurements.

2. HVAC Systems: Heating, ventilation, and air conditioning

(HVAC) systems require temperature sensors for controlling

and maintaining comfortable indoor environments. Tapered

thermowells can be employed in HVAC applications to improve

the response time of temperature sensors, allowing for

quicker adjustments and more precise control of heating and

cooling systems.

3. Power Generation: Power plants, including those based on

fossil fuels, nuclear energy, or renewable sources, often

rely on temperature measurements for equipment monitoring

and control. Tapered thermowells can be used in critical

areas, such as steam turbines or boilers, where rapid

temperature changes occur and fast response times are

necessary to ensure safe and efficient operation.

4. Food and Beverage Industry: Temperature monitoring is

vital in food and beverage production to ensure quality,

safety, and regulatory compliance. Tapered thermowells can

be employed in applications such as food processing,

brewing, or pasteurization, where quick and accurate

temperature measurements are required for optimal product

quality and safety.

5. Automotive and Aerospace: Tapered thermowells can find

application in automotive and aerospace industries for

temperature sensing in engine components, exhaust systems,

or aerodynamic testing. These industries often require fast

response times to monitor temperature changes and ensure

efficient operation and safety.