VAISHNAV INSTRUMENTS offer bar stock thermowells / sleeves are designed to meet standards established by bsi,din,asme and other authorities.

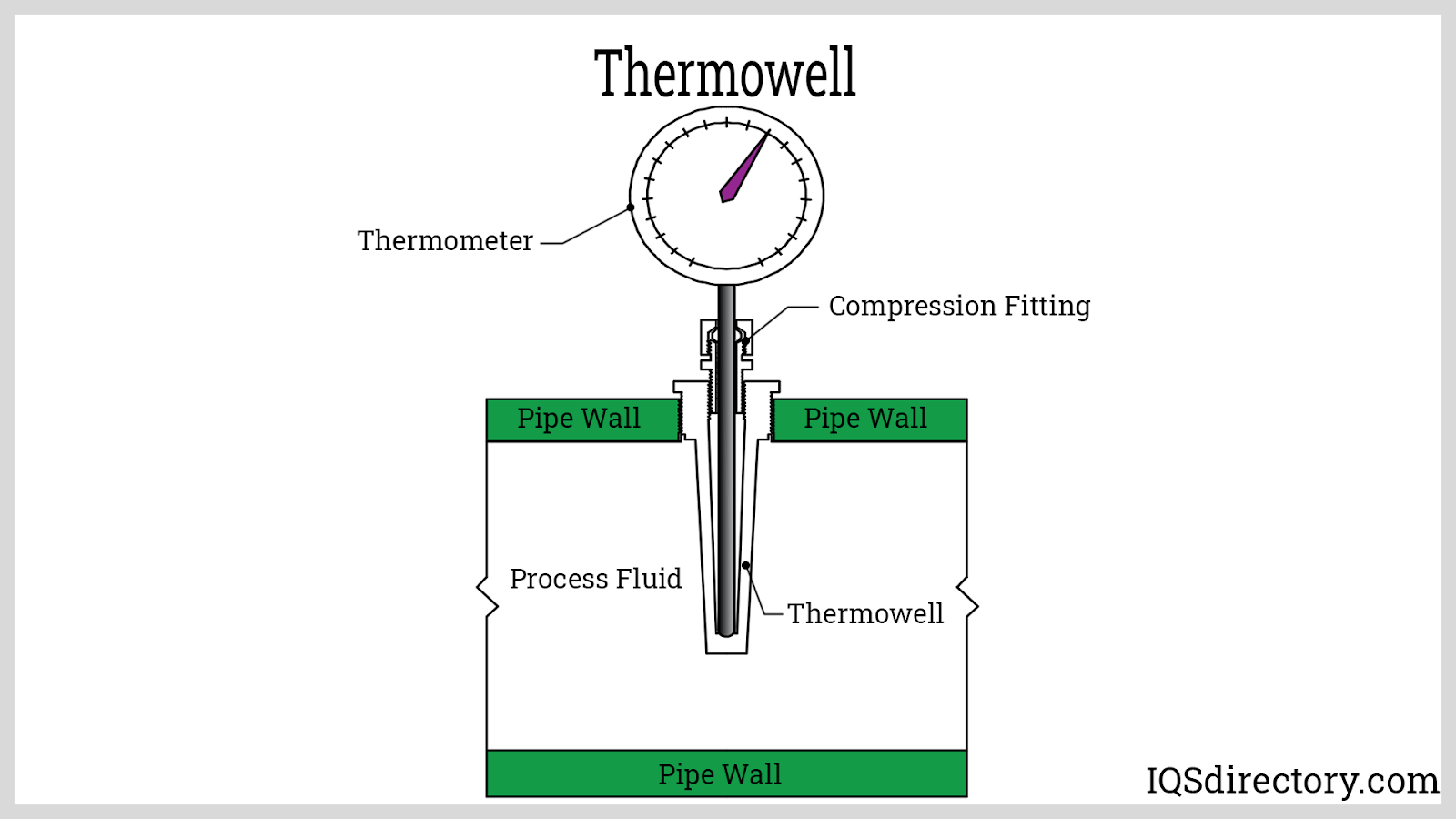

Many industrial processes require harsh environments and extreme temperatures for their operation. Temperature measurement is a challenge in such circumstances.Besides heat, there can be other conditions such as high pressure and powerful chemical substances, radioactivity etc. A regular temperature sensor may fail to stand in such an aggressive environment.Therefore, some device is required to guarantee the mechanical protection of this equipment. Thermowell acts as the medium of mounting these temperature sensors in industrial processes and protecting them.

Drilled Bar Stock Thermowell:

Our thermowell bodies are machine and drilled from solid bar stock. this results in a non-welded water tight unit. High accuracy machines are used to ensure concentricity of the bore with respect to the outside diameter and a the thermowell.

CONFIGURATION STEM STYLE IN:

Tapered, stepped or straight style and machine to ensure compatibility with process requirement. tapered and stepped style thermowells increases the speed of response whilst maintaining its mechanical strength.

FLANGE MOUNTED THERMOWELL:

we supply flange mounted thermowel to ansi b16.5 standard and pound ratings ranging from 150ib/sq in to 2500ib/sq in. other standard flanges like din, jis, ring joint facing (rtj), and cover flange are available, special machined nozzle thermowell (shell standard) are also available.

THREADED MOUNTED THERMOWELL:

A comprehensive range of thermowells machined from solid bar

stock can be designed and fabricated to customer's

requirement. following types of thread are commonly supplied:

npt bsp metric etc.

pocket thermowell: pocket thermowell offers a lower cost

alternative to solid drilled construction where high pressure

is not a design consideration. they are fabricated from high

quality seamless tube or schedule pipes with ends sealed with

welded plug.

STANDARD MATERIALS:

sst. 304, sst316/ 316L, carbon steel, brass etc.

SPECIAL ALLOY MATERIAL:

inconel hastelloy, titanium, monel, teflon etc.

WELDING:

welding are accordance to asme ix. quality assurance & testing all materials used are of the highest quality and strict control is applied to both material selection and manufacturing processes. inspection including the following:

full dimensional check as standard bore concentricity check as standard dye penetrant test on welded joints only as standard hydrostatic testing of up to max. 10,000 psi as option requirement radiographic testing on the well body as option requirement

Certification including material certificates from supplier and steel mill certificates can be provided and documents of in-house testing as well as third party certification on products can be provided in compliance to international and user standard.

INDENTIFICATION DATA:

the serial, heat and reference are stamped or electro-etached on each thermowell for identification purposes. additional tagging in accordance with customer's requirement is also available.

2. Thermowells guarantee that a sensor receives the process temperature (proper heat transfer).

3. Thermowells provide better precision from improved heat transfer in the piping systems where they are employed.

4. Thermowells permit the removal of a sensing component while keeping the rest of a system operational.

2. Weld-in thermowells

3. Socket weld thermowells

4. Flanged thermowells

5. Scruton Thermowells

6. Van Stone thermowells

7. Sanitary Thermowells

Thermowell Applications

The petrochemical, food processing, refinery, cosmetics, chemicals, power generation, pharmaceutical industries are only a few of the industrial fields where thermowells are used. Thermowells protect their equipment from external forces and disturbances, including pressure, abrasion, vibration, and corrosion, that the medium being processed may bring. In addition, thermowell-protected sensors can be taken out and replaced without damaging the manufacturing environment in any other way.

Advantages of Thermowells

Thermowells provide an invaluable service by enhancing the process of measuring temperature in several ways. They provide protection from corrosion, high material velocities, and extreme pressure damage. Thermowells allow for the replacement of temperature sensors without draining the system. In short, thermowells exist in order to save money in industries where applied. Below, is a summary of some factors to consider regarding a thermowell’s cost savings.

1. Longevity

2. Sensor Replacement Cost Analysis

3. Labor Costs

4.No Shut-Downs